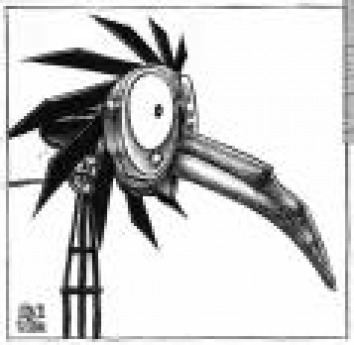

Critical eye on things

Design, Manufacturing, Site delivery, Operation and Maintenance deserve a critical eye and inspection expertise. As head of quality assurance for two major turbine manufactures, rest assured that the experience is there to get to the bottom of your problem.

Our network will apply the best and most cost efficient methodology for investigation whatever your problem may be.

Inspections need not be limited to technical problems. Process and methodologies can be reviewed for due diligence drawing on our expertise as Lead Auditors for QMS (ISO 9001), EMS (ISO 14000), and Health & Safety (OHSAS 18000).

Turbine health check

Foundation bolts

Rotor and drive train alignment

Nacelle vibration measurement & analysis

Acoustic and thermographic imaging

Load and fatigue testing

Durability

Performance

Noise levels

As non-invasive as possible to prevent unwarranted downtime.

Blade inspection

Manufacturing documentation

Complete-Comprehensive-Concise

Process evaluation

Final inspection

Site receipt inspection

Realization evaluation

Damage inspection

Certification

Design simulation

Load and fatigue testing

Durability

Performance

Acoustic

Our network will apply the best and most cost efficient methodology for investigation whatever your problem may be.

Inspections need not be limited to technical problems. Process and methodologies can be reviewed for due diligence drawing on our expertise as Lead Auditors for QMS (ISO 9001), EMS (ISO 14000), and Health & Safety (OHSAS 18000).

Turbine health check

Foundation bolts

Rotor and drive train alignment

Nacelle vibration measurement & analysis

Acoustic and thermographic imaging

Load and fatigue testing

Durability

Performance

Noise levels

As non-invasive as possible to prevent unwarranted downtime.

Blade inspection

Manufacturing documentation

Complete-Comprehensive-Concise

Process evaluation

Final inspection

Site receipt inspection

Realization evaluation

Damage inspection

Certification

Design simulation

Load and fatigue testing

Durability

Performance

Acoustic